Rubber and Plastic Insulation Benefits and Applications in Modern Construction

Rubber and plastic insulation materials are widely used in modern construction due to their excellent thermal performance, moisture resistance, and durability. These insulation solutions are essential for residential, commercial, and industrial buildings, helping to reduce energy consumption, improve indoor comfort, and provide fire and acoustic protection.

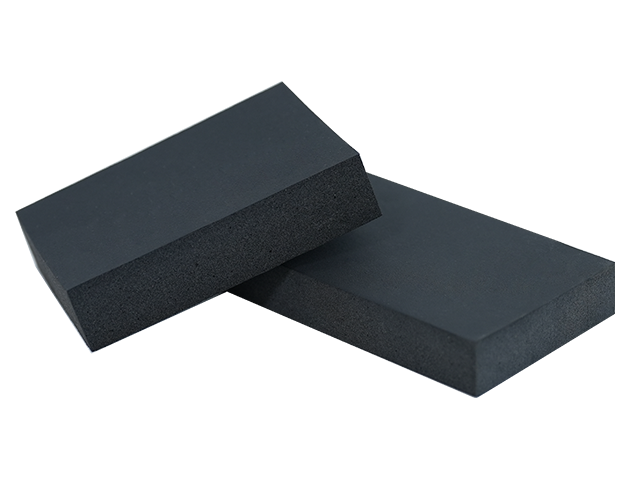

Manufactured from synthetic polymers and elastomers, rubber and plastic insulation comes in various forms such as sheets, rolls, tubes, and panels. These materials are suitable for walls, ceilings, roofs, pipes, ducts, and specialized HVAC systems, making them versatile and cost-effective solutions for building efficiency and sustainability.

This article provides a detailed overview of rubber and plastic insulation, including installation procedures, operational workflows, real-world applications, and key performance features, offering practical guidance for architects, contractors, and B2B buyers.

Rubber and plastic insulation materials are designed to reduce heat transfer, minimize energy loss, and protect structural components. They are lightweight, flexible, and resistant to environmental factors, making them ideal for a range of construction applications.

Thermal Insulation: Maintains stable indoor temperatures by reducing heat transfer.

Moisture Resistance: Prevents condensation, mold, and corrosion in pipes and walls.

Fire Resistance: Many rubber and plastic insulation products meet fire safety standards.

Durability: Long-lasting and resistant to chemical and physical degradation.

Soundproofing: Absorbs and dampens sound, enhancing acoustic comfort.

Eco-Friendly Options: Some products incorporate recycled materials and are recyclable.

Sheets and Panels: Used in walls, ceilings, and roof insulation.

Rolls and Mats: Flexible for large surfaces, easy to cut and fit.

Tubing and Pipe Covers: Specialized for HVAC and plumbing systems.

Sprayable Plastic Foam: Provides seamless coverage for walls and cavities.

Rubber and plastic insulation reduces heat flow, helping buildings maintain consistent temperatures in summer and winter. This results in lower energy bills and improved comfort.

Closed-cell rubber and plastic insulation prevents water vapor from penetrating walls or pipes. This minimizes mold growth, corrosion, and structural damage, especially in high-humidity areas.

Many rubber and plastic insulation products are non-combustible or self-extinguishing, contributing to fire prevention in residential and commercial buildings.

The density and flexibility of rubber insulation allow it to absorb sound, reducing noise transmission through walls, floors, and ducts.

Rubber and plastic insulation materials are resistant to chemical exposure, UV degradation, and mechanical stress, ensuring long-term performance with minimal maintenance.

Performance testing is crucial to ensure that rubber and plastic insulation meets energy, safety, and acoustic standards.

| Parameter | Typical Values | Description |

|---|---|---|

| Thermal Conductivity | 0.030–0.045 W/m·K | Resistance to heat flow |

| Fire Rating | Class B or self-extinguishing | Fire safety compliance |

| Water Absorption | <2% | Prevents mold and corrosion |

| Acoustic Absorption | 0.7–0.95 | Reduces noise transmission |

| Compressive Strength | 100–200 kPa | Maintains shape under pressure |

| Density | 50–250 kg/m³ | Influences thermal and acoustic properties |

The R-value measures insulation effectiveness. Rubber and plastic insulation typically ranges from R-3 to R-5 per inch, depending on density and thickness, offering significant energy savings when properly installed.

Proper installation ensures optimal thermal efficiency and longevity of rubber and plastic insulation.

Measure insulation area and select the appropriate type, thickness, and density.

Ensure installation surfaces are clean, dry, and free of debris.

Check local building codes for insulation requirements.

Use a utility knife or insulation saw to cut sheets, rolls, or tubing.

Cut slightly larger than the cavity for a snug fit.

Wear protective gloves and masks to prevent irritation from fibers or dust.

For sheets or panels: place tightly against the surface without compression.

For tubing: slide over pipes ensuring full coverage.

For rolls or mats: unroll and secure evenly across the surface.

Adhesive, staples, or friction-fit methods may be used.

Seal joints with insulation tape to prevent air gaps.

Install vapor barriers if required for humid or wet areas.

Inspect all seams, edges, and joints for gaps or compression.

Cover with drywall, panels, or ceiling boards as needed.

Document installation for maintenance records.

Survey building structure.

Select insulation type and thickness.

Prepare materials and tools.

Cut insulation to size.

Fit insulation tightly in walls, ceilings, or around pipes.

Secure with adhesives, fasteners, or friction fit.

Seal joints and inspect for consistency.

Conduct thermal and acoustic testing.

Perform visual inspection for gaps or compression.

Record installation details for warranty and maintenance purposes.

Walls and Ceilings: Reduces heat loss and maintains indoor comfort.

Pipes and Ducts: Prevents condensation and heat loss in HVAC systems.

Roof Insulation: Enhances energy efficiency and weather resistance.

Offices and Hotels: Acoustic panels with rubber cores for noise reduction.

Shopping Centers: Energy-efficient insulation for large spaces.

Restaurants: Moisture-resistant insulation in kitchens and cold storage areas.

Chemical Plants: Rubber insulation resists chemicals and high temperatures.

Refrigeration Units: Plastic insulation maintains cold chain efficiency.

Manufacturing Plants: Acoustic and thermal insulation for operational efficiency.

Residential Retrofit: Rubber insulation on HVAC ducts reduced energy bills by 20%.

Office Building: Plastic insulation in walls improved indoor thermal comfort and reduced HVAC cycles.

Industrial Plant: Rubber pipe insulation minimized condensation and corrosion, extending equipment lifespan.

| Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Annually | Check for moisture, gaps, or compression |

| Joint and Seal Check | Every 2–3 years | Maintain airtight and thermal integrity |

| Cleaning | Every 1–2 years | Remove dust and debris from exposed insulation |

| Replacement | As needed | Restore thermal and acoustic performance |

Inspect for water leaks or mold regularly.

Avoid compressing insulation during renovations.

Ensure vapor barriers remain intact.

Replace damaged sections promptly.

Store spare insulation in a dry, ventilated area.

Energy Efficiency: Reduces heating and cooling costs.

Moisture Control: Prevents condensation and mold growth.

Fire Safety: Meets or exceeds fire safety standards.

Acoustic Comfort: Reduces noise in residential and commercial buildings.

Durable and Long-Lasting: Resistant to chemical, mechanical, and environmental damage.

Versatile: Suitable for walls, ceilings, roofs, pipes, and ductwork.

Rubber and plastic insulation materials are versatile, durable, and highly effective in improving thermal efficiency in modern construction. With proper installation, adherence to operational workflows, and routine maintenance, these materials contribute to energy savings, indoor comfort, fire safety, and acoustic performance.

Whether for residential homes, commercial buildings, or industrial facilities, rubber and plastic insulation is a cost-effective solution for achieving modern building performance and sustainability goals.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

이 웹사이트는 귀하가 당사 웹사이트에서 최상의 경험을 할 수 있도록 쿠키를 사용합니다.

논평

(0)